SBR Sequential Batch Reactor

The sequential batch reactor, often called the SBR biological reactor, represents an economical option for effluent treatment since all processes are in the same tank.

Its main advantages are space savings and flexibility in managing industrial effluents produced in batches.

The SBR reactor consists of a tank or a set of tanks where the activated sludge water treatment process is carried out in batches.

SBR Sequential Batch Reactor Cycles

- Filling: The effluent enters the tank over the settled sludge remaining after the settling and sludge removal process. The filling can be anoxic, aerated, or combined. Adequate distribution of the inlet flow guarantees proper mixing.

- Reaction: The inlet flow stops and the reaction process begins with aeration and mixing achieving the biodegradation of the substrate.

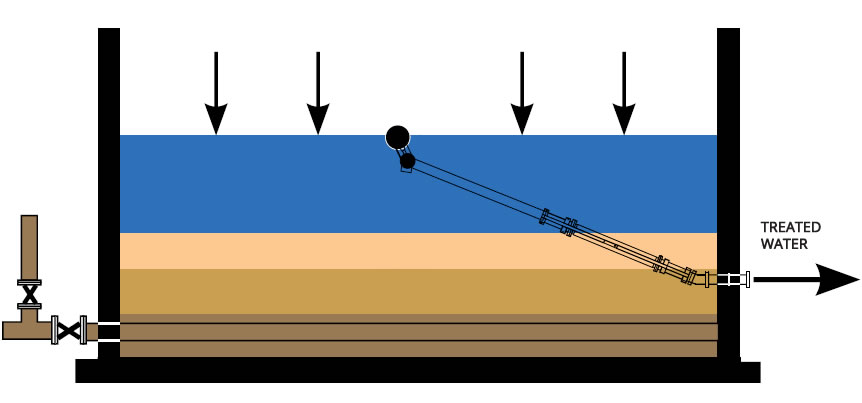

- Sedimentation: Aeration and mixing stop and the biomass sedimentation process begins, leaving the clear supernatant liquid or treated water.

- Decantation: The decanter sucks the effluent just below the surface and must be capable by design of removing the clear fluid free of solids and scum.

- Sludge Disposal: In this phase, the reactor is waiting to receive more influent, and sludge is removed from the bottom.

There are different options for aeration in a SBR Sequential Batch Reactor, such as:

- Floating Aerators

- Aeration Grills with Fine Coarse Bubble Diffusers

- Jet Type Aerators

In the same way that it is a flexible system, in terms of the type of aeration mechanisms, it is also flexible in terms of the geometry of the tanks, which can be rectangular, circular, or cylindrical.

At Sumio Water we can offer you a solution adapted to the particular needs of your project.

The SBR requires a control system to manage cycles and times. Level switches and automatic valves, in addition to a programmable logic controller, are necessary.

Decanters

Regarding the decanting phase, there are several designs of decanting mechanisms, among which are:

- Pivot with linear actuator

- Floating box type

- Floating tubular decanter